Why Hybrid Encapsulation?

The latest trends in the display market can be represented with the keywords such as flexible, large panel and high resolution. And companies are releasing the products applying a flexible AMOLED panel like Galaxy Note Edge, Galaxy Gear S, and G Watch R and high-resolution products applying a large area panel such as UHD curved 65- and 77- inch in the AMOLED market. For Flexible AMOLED panel, foldable and rollable features are required whereas the resolution over UHD level and the brightness at least 500nit are required for a large area AMOLED panel.

There still are many issues to be resolved to mass-produce a flexible AMOLED panel and a large area AMOLED panel with the resolution above UHD level. Especially the encapsulation is a technology deemed to transform as the OLED manufacturing technology changes and it is a very critical area for it is the last process determining the panel yield rate.

Encapsulation is essential process to prevent emitting and electrode materials from being oxidized as it blocks moisture and oxygen flowing in from the outside of OLED element, and protects elements from mechanical and physical impacts from outside.

According to the “OLED Encapsulation Report” issued by the UBI Research on the 5th, the key encapsulation technology applicable for every application is expected to be the hybrid encapsulation.

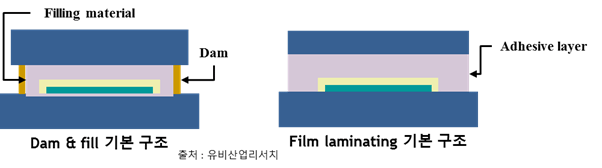

The Hybrid Encapsulation structured with a thin-film passivation, a cover plate with a gas barrier property, and polymer to adhere a thin-film passivation and cover plate in two applications ? the ‘Dam & Fill’ uses polymer in liquid form while the ‘Film Laminating’ uses it as processed in film form.

The frit glass method which is employed in the rigid AMOLED for a mobile device currently on sale is a perfect encapsulation method but it is hard to be applied to a large panel and flexible AMOLED. The TFE (Thin Film Encapsulation) technology which is applied to some flexible AMOLED is also inapplicable for a large panel due to the complicated process of forming a multilayer thin film, the occurrence of particle, and the problem of film uniformity.

However, the hybrid encapsulation is valid for both a large panel and flexible OLEDs with the advantage that the number of process is less than that of TFE. UBI research analyzed that the hybrid encapsulation using a transparent gas barrier can be applied to a rigid AMOLED panel for a mobile device for the benefits of preventing breaks and reducing thickness.

As the hybrid encapsulation is applied in a large area OLED and flexible OLED panels which is to be the core of future OLED industry, UBI Research prospected the main material market for hybrid encapsulation to form US$600 billion in 2015 and to show CAGR of 74% between 2015-2020. The primary materials applied in the hybrid encapsulation are organic materials, metal foil and transparent gas barrier.