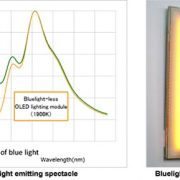

Mitsubishi Chemical and Pioneer Develops Bluelight-less OLED Lighting

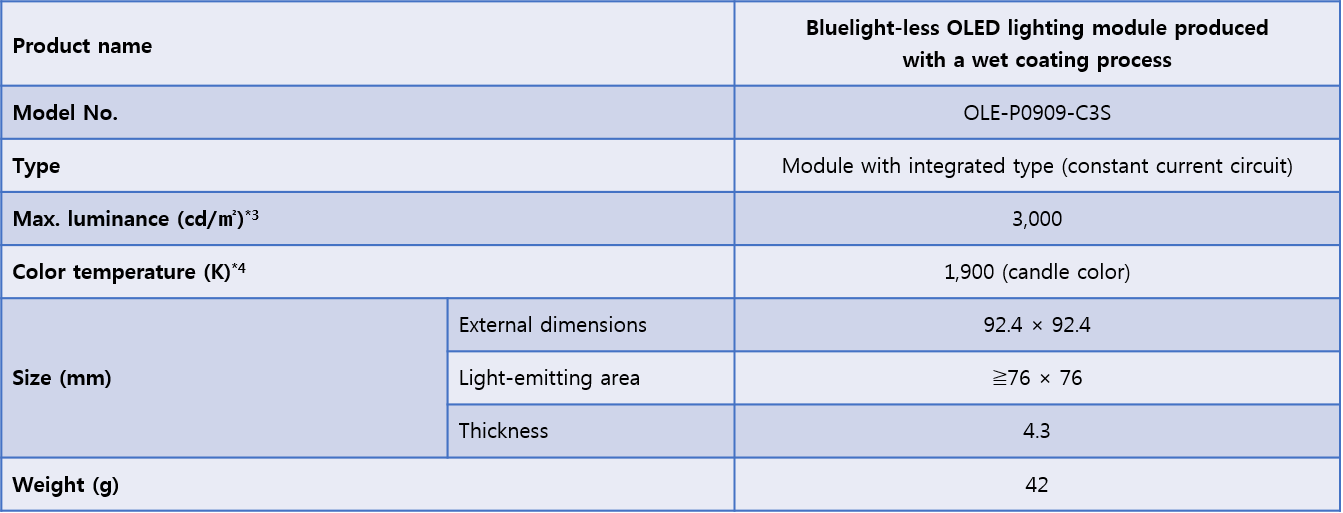

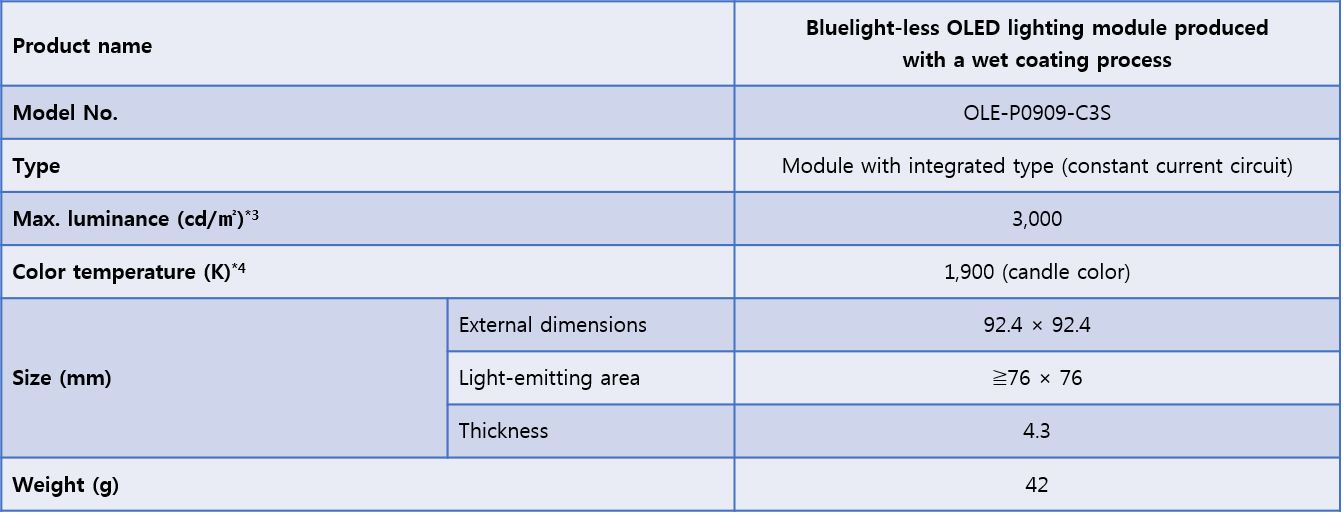

Japan’s Mitsubishi Chemical and Pioneer announced their success in developing the first bluelight-less OLED lighting module. The two companies produced this module through a wet coating process for the light-emitting layer and began shipping samples on August 1.

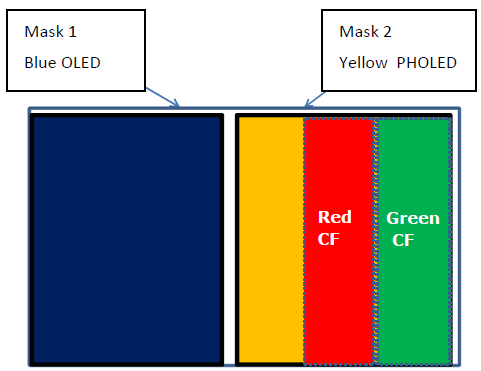

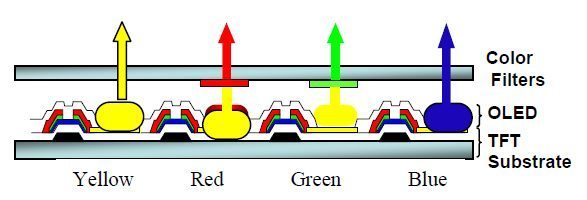

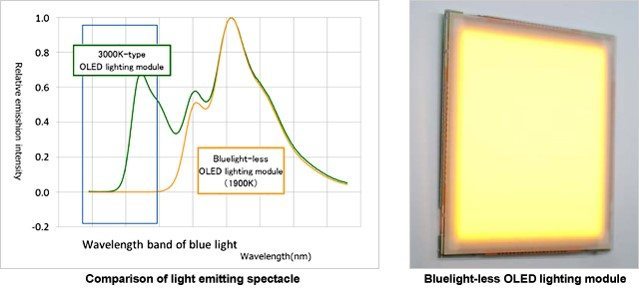

The new OLED lighting module does not use blue emitting materials in the OLED panel and the light from the panel contains a minimal portion of blue light. According to the companies, this is less than 1% of the amount in the 3000K-type OLED lighting module developed by Mitsubishi Chemical and Pioneer.

The panel is a candle-color type with a 1900K color temperature; this is suitable for storage lighting of light-sensitive items such as cultural heritage and paintings, as well as lighting for bedrooms and medical practices.

Blue light, which has a wavelength of between 380 and 495 nanometers, has the highest energy among visible light. This is enough to reach the retina at almost full strength. This can cause eye fatigue as well as reduction in quality sleep.

With the increase of smartphone and PC use, the amount of time exposed to blue light is also increasing. Therefore, as the interest in eye health rises, this bluelight-less OLED lighting module development is worthy of attention.