[Lighting Japan 2016] What is the Key Issue of Solution OLED Materials?

In Lighting Japan 2016 (January 13-16) conference, Sumitomo Chemical and Merck revealed recently developed soluble OLED materials performance results.

The soluble OLED materials efficiency published in this conference reached ≥ 65% of UDC’s evaporation materials; particularly, Sumitomo Chemical’s red achieved ≥ 85%, and green reached ≥ 88% of UDC’s evaporation materials efficiency. Lifetime (LT 95) results were not as good as efficiency with red’s 25% and green’s approximately 40% (average).

Sumitomo Chemical and Merck both revealed that although in terms of efficiency the soluble materials almost caught up to evaporation materials, but lifetime requires further development.

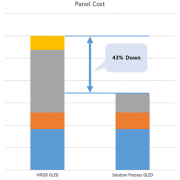

Solution process is a method that allows for large area OLED panel production in RGB method using ≥ Gen8 manufacturing equipment. Key panel companies are actively carrying out research development, and the performance of soluble OLED material is considered the biggest issue. According to Solution Process OLED Report 2015, published by UBI Research, when solution process is applied the material cost can be approximately 40% reduced compared to the current evaporation process using large area OLED panel. The timing for the solution process application to mass production is expected to be decided depending on the development speed of soluble OLED materials.

OLED Materials Performance Comparison

댓글을 남겨주세요

Want to join the discussion?Feel free to contribute!